Nuestra Visión

Innovación Continua

Creemos en el poder creativo de nuestra gente, apostando a la diferenciación y el desarrollo

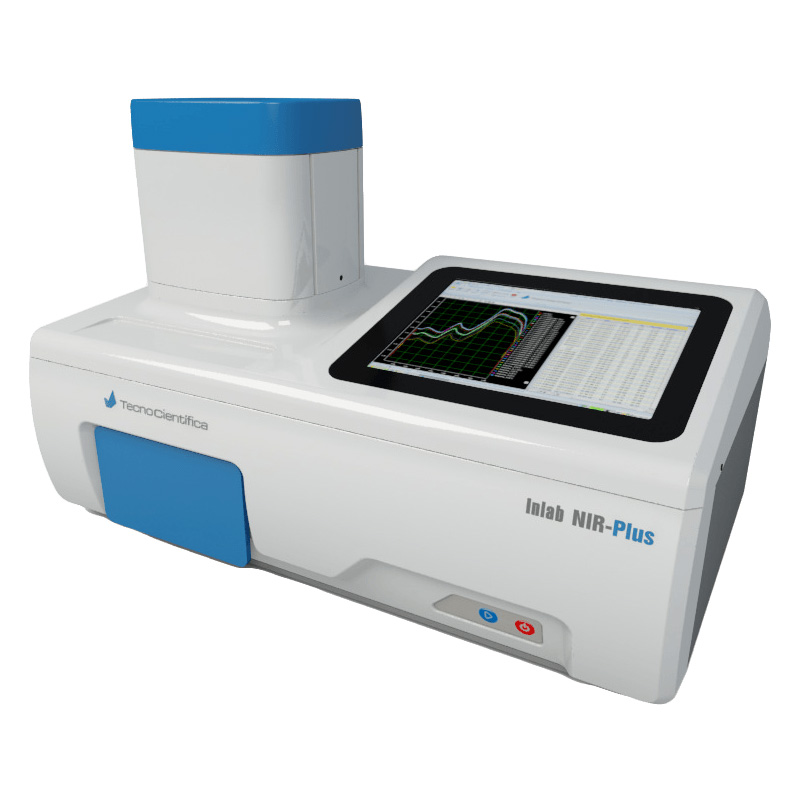

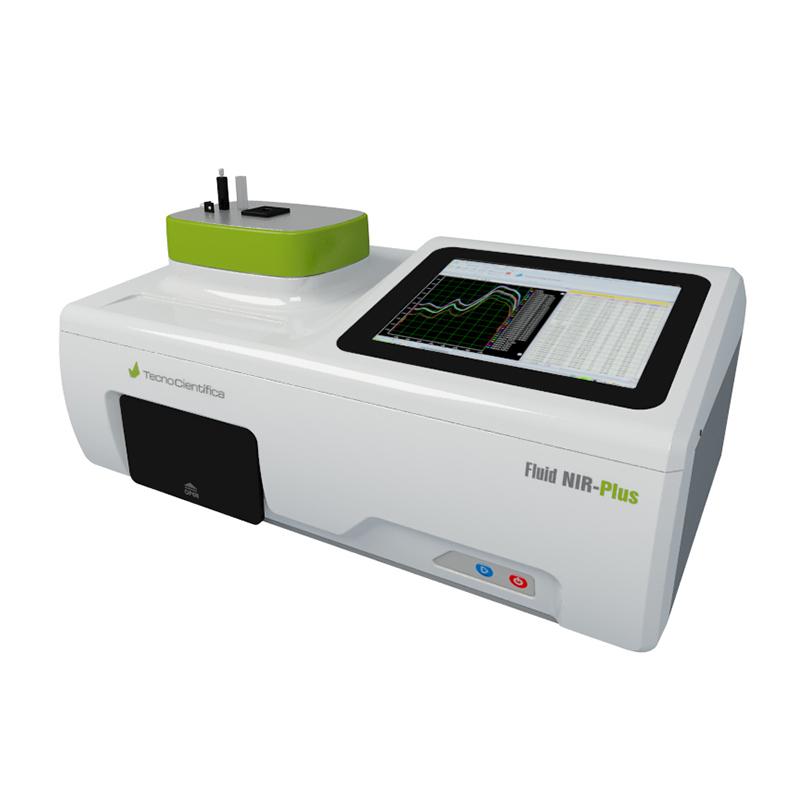

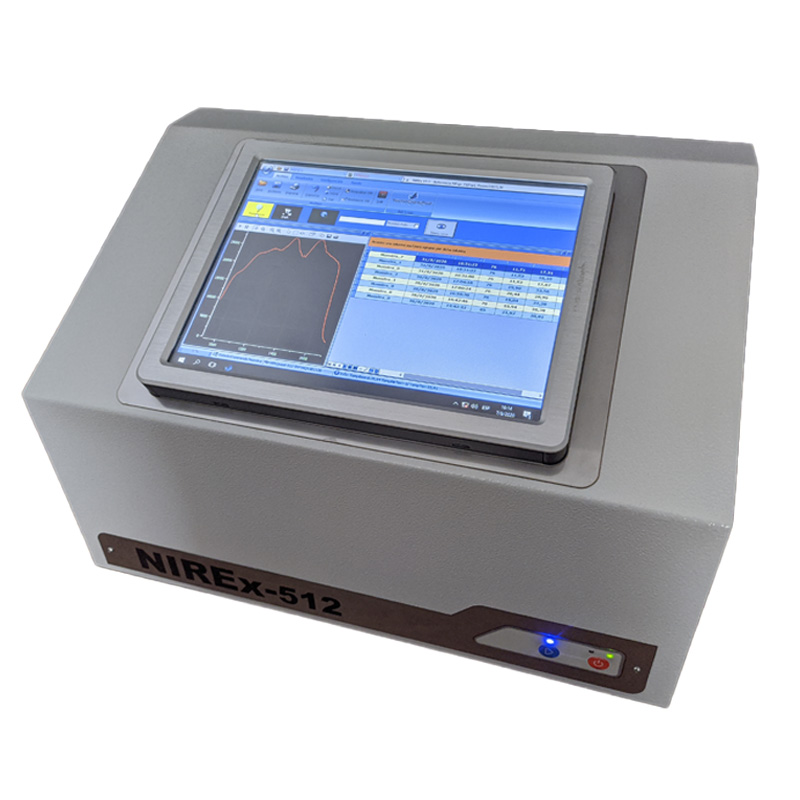

Tecnología Moderna

El único camino que conocemos para lograr nuestros objetivos es basarnos siempre en la tecnología más avanzada

Soporte Técnico

Nuestros Clientes son nuestro más Valioso Capital. Nuestra vocación de servicio: La marca que nos Identifica